Maximizing Efficiency and Performance of Diesel Generators for Inductive Loads

Introduction

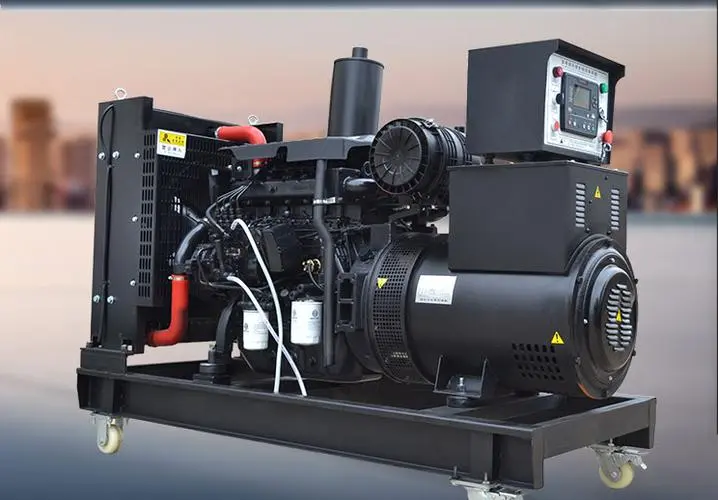

Diesel generators play a vital role in providing backup power for various applications, including industrial, commercial, and residential settings. When it comes to powering inductive loads such as motors, transformers, and other equipment with high starting currents, diesel generators must be properly sized and equipped to handle the unique characteristics of these loads. In this article, we will explore the challenges of powering inductive loads with diesel generators, the considerations for selecting the right generator, and the best practices for maximizing efficiency and performance.

Understanding Inductive Loads

Inductive loads are characterized by the presence of inductance, which causes a phase shift between voltage and current. This phase shift leads to a lagging power factor, which can result in higher current draw during startup and operation. Common examples of inductive loads include electric motors, transformers, pumps, and compressors.

When powered by a diesel generator, inductive loads can pose challenges due to their high starting currents and transient behavior. The generator must be able to provide enough power to overcome the initial surge in current during startup while maintaining stable voltage and frequency levels throughout the operation.

Challenges of Powering Inductive Loads with Diesel Generators

One of the main challenges of powering inductive loads with diesel generators is the need to handle the high starting currents required by these loads. Electric motors, for example, can draw several times their rated current during startup, placing a significant strain on the generator. If the generator is undersized or not properly configured, it may struggle to deliver the necessary power, leading to voltage dips, frequency fluctuations, and potential damage to the equipment.

Another challenge is the impact of inductive loads on generator efficiency. The reactive power component of inductive loads can reduce the overall power factor of the system, resulting in increased losses and reduced fuel efficiency. Diesel generators are designed to operate most efficiently at a specific load and power factor, so the presence of inductive loads can affect their performance and longevity.

Considerations for Selecting the Right Generator

When selecting a diesel generator for powering inductive loads, several key factors must be taken into account to ensure optimal performance and reliability:

1. Power Rating: The generator must be sized appropriately to handle the peak starting currents of the inductive loads without exceeding its capacity. It is essential to consider both the rated power and the transient power requirements of the equipment being powered.

2. Voltage Regulation: Inductive loads are sensitive to voltage fluctuations, so the generator must be equipped with a robust voltage regulation system to maintain stable voltage levels under varying load conditions.

3. Power Factor: Diesel generators are typically rated for a specific power factor, so it is important to consider the impact of inductive loads on the overall power factor of the system. A generator with power factor correction capabilities may be necessary to improve efficiency and performance.

4. Transient Response: The generator must have a fast transient response to accommodate the sudden changes in load demand from inductive loads. This requires a well-designed control system and sufficient reserve capacity to handle the transient power requirements.

Best Practices for Maximizing Efficiency and Performance

To maximize the efficiency and performance of diesel generators for inductive loads, the following best practices should be followed:

1. Proper Sizing: Ensure that the generator is properly sized to handle the peak starting currents of the inductive loads while maintaining a sufficient margin for future expansion. Undersized generators are more prone to voltage dips and frequency fluctuations, which can damage equipment and disrupt operations.

2. Voltage Regulation: Regularly calibrate and maintain the voltage regulation system of the generator to ensure stable voltage levels under varying load conditions. Voltage fluctuations can cause motor overheating and premature failure, so it is crucial to monitor and control voltage within acceptable limits.

3. Power Factor Correction: Consider installing power factor correction equipment to improve the overall power factor of the system and reduce losses associated with reactive power. This can help optimize generator efficiency and reduce fuel consumption.

4. Load Management: Implement load shedding or load management strategies to prioritize critical loads and minimize the impact of inductive loads on the generator. By strategically controlling the operation of equipment, it is possible to reduce peak demand and improve overall system reliability.

5. Maintenance and Monitoring: Regular maintenance and monitoring of the generator are essential to detect potential issues early and prevent costly downtime. Inspect and test the generator, fuel system, cooling system, and control components on a routine basis to ensure optimal performance.

Conclusion

Diesel generators are a reliable source of backup power for various applications, including inductive loads with high starting currents. By understanding https://www.lkpowerplant.com/400kw/ of powering inductive loads with diesel generators and following best practices for selection and operation, it is possible to maximize efficiency and performance while ensuring the reliability of the system. Proper sizing, voltage regulation, power factor correction, load management, and maintenance are key considerations for achieving optimal results when using diesel generators for inductive loads. By implementing these strategies, operators can enhance the resilience of their power systems and minimize the risk of downtime and equipment damage.